Zinc Dust

Product Details:

Zinc Dust Price And Quantity

- 500 Kilograms

- 250 INR/Kilograms

Zinc Dust Trade Information

- Others

- 10000 Kilograms Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

Product Description

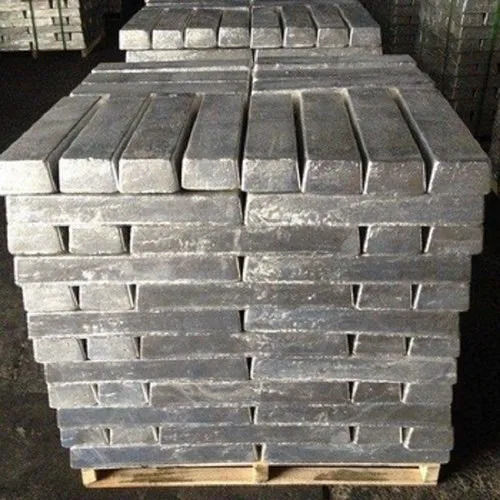

What is Zinc Dust?

Zinc dust is a fine powder made from zinc metal, commonly produced through atomization or chemical processes. It is highly reactive and known for its excellent corrosion-resistant properties. Zinc dust is primarily used in industrial applications, such as corrosion protection, galvanizing, and chemical manufacturing. It has a grayish appearance and a high surface area, making it ideal for various chemical processes.

Top Industrial Uses of Zinc Dust

Zinc dust is widely used across several industries due to its versatility and protective qualities. Some common uses include:

- Corrosion Protection: Zinc dust is used in protective coatings, often applied to steel structures, pipelines, and other metal surfaces to prevent rust and corrosion.

- Chemical Manufacturing: It plays a crucial role in producing chemicals like zinc oxide and in various redox reactions.

- Battery Production: Zinc dust is utilized in the production of batteries, particularly zinc-carbon and alkaline types.

Zinc Dust in Corrosion Protection

Overview of Zinc Dust

Zinc dust is a crucial component for preventing corrosion, especially in coating applications. Applying zinc dust to metal surfaces creates a barrier that shields them from oxidation and rust. The term "galvanisation" is frequently used to describe this process when combined with other materials. In industries like construction, automotive, and marine where exposure to damp and harsh conditions is common, zinc dust is very helpful.

Applications in Various Industries

Zinc dust's corrosion resistance makes it valuable in a variety of fields, including:

- Construction: Applied as a protective coating for structural steel and bridges.

- Marine: Used on ships, offshore rigs, and other equipment exposed to saltwater.

- Automotive: Prevents corrosion on car parts and exhaust systems.

Advantages and Unique Properties

Zinc dust offers several benefits, including:

- High Corrosion Resistance: Protects metal surfaces from rust and oxidation, extending their lifespan.

- Chemical Stability: Acts as a reducing agent in various chemical processes.

- Cost-Effective: Provides a durable, low-cost solution for corrosion prevention and chemical reactions.

Safety Precautions for Handling Zinc Dust

While zinc dust is highly beneficial, it must be handled with care due to its reactive properties. Important safety tips include:

- Protective Gear: Wear gloves, goggles, and respiratory protection to avoid inhaling dust particles.

- Ventilation: Ensure proper ventilation in the workspace to prevent the buildup of hazardous fumes, especially during mixing or heating processes.

- Storage: Store zinc dust in airtight containers away from moisture and incompatible materials to avoid unwanted reactions.

- Disposal: Dispose of zinc dust in accordance with local environmental regulations to prevent contamination.

FAQs About Zinc Dust

Is zinc dust flammable?

Yes, zinc dust can be flammable when exposed to high heat or fire. Proper storage and handling are essential to prevent ignition.

Can zinc dust be used in all industries?

Zinc dust is primarily used in industries that require corrosion protection and chemical reactions. It may not be suitable for applications where its reactivity could pose a risk.

How does zinc dust protect against corrosion?

Zinc dust acts as a sacrificial anode. It corrodes first, protecting the underlying metal from oxidation.

What are the environmental impacts of zinc dust?

Zinc dust can be harmful if not disposed of properly, potentially contaminating water and soil. Safe disposal practices are necessary.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+