Working hours : Mon - Sat : 10AM - 7PM

धातु उत्पादहमारे धातु उत्पादों में स्टेनलेस स्टील, एल्यूमीनियम, तांबा और मिश्र धातुओं सहित टिकाऊ सामग्री से तैयार की गई वस्तुओं की एक विस्तृत श्रृंखला शामिल है। हमारी कंपनी द्वारा उपयोग किए जाने वाले ऐसे उत्पादों की विस्तृत श्रृंखला है जो आमतौर पर धातु विज्ञान और विनिर्माण उद्योगों में उपयोग किए जाते हैं। हमारे प्रस्ताव निर्माण, निर्माण और उपभोक्ता बाजारों को पूरा करते हैं, जिससे गुणवत्ता और विश्वसनीयता सुनिश्चित होती है। विभिन्न अनुप्रयोगों और उद्योगों के लिए बहुमुखी समाधान प्रदान करने वाले औद्योगिक मानकों वाले धातु उत्पादों के व्यापक चयन का पता लगाएं। हमारे द्वारा इन उत्पादों को उचित मूल्य पर थोक में ऑर्डर करें।

|

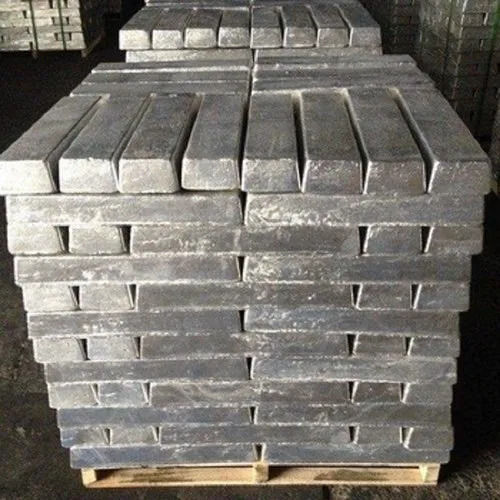

मैग्नीशियम स्लैब

Magnesium Slab Overview and Applications

A magnesium slab is a solid block of metallic magnesium typically produced through casting processes Magnesium slabs are valued for their lightweight high strengthtoweight ratio and excellent machinability making them crucial in industrial and commercial applications

Key Properties of Magnesium Slabs

Appearance Silverygray metal with a smooth surface

Lightweight Magnesium is the lightest structural metal with a density of 174 gcm

Machinability Easy to machine weld and fabricate compared to other metals

Corrosion Resistance Enhanced when alloyed with other elements like aluminum or zinc

StrengthtoWeight Ratio High making it ideal for applications requiring strength without added weight

Manufacturing of Magnesium Slabs

1 Primary Processes

Casting Molten magnesium is poured into molds to form slabs

Direct Chill Casting A controlled cooling process for producing large highquality slabs

2 PostProcessing

The slabs may undergo rolling cutting or heat treatment for specific industrial requirements

Applications of Magnesium Slabs

1 Aerospace and Automotive

Used in lightweight structural components like brackets housings and panels

Reduces weight in vehicles and aircraft enhancing fuel efficiency

2 Electronics

Magnesium slabs are machined into parts for consumer electronics including laptops cameras and mobile phones

3 Construction

Utilized in building materials where lightweight strong metals are required

4 Medical Devices

Magnesiums biocompatibility makes it suitable for certain implants or medical instruments

5 Tooling and Molds

Magnesium slabs are shaped into molds and dies for various manufacturing processes

6 Defense and Military

Used in applications where lightweight and durable materials are critical such as in militarygrade equipment

Advantages of Magnesium Slabs

EcoFriendly Magnesium is recyclable and has a lower environmental footprint compared to heavier metals

Thermal Conductivity Efficient heat dissipation beneficial in electronics and automotive parts

CostEfficiency Offers reduced material costs for weightsensitive applications

Safety and Handling

Storage Keep in a dry ventilated area to avoid oxidation or corrosion

Machining Precautions

Magnesium dust can be highly flammable ensure proper ventilation and dust collection systems

Avoid sparks and high heat during machining

SEO Tips for Magnesium Slab Content

1 Target Keywords

Primary Magnesium slab magnesium slab uses lightweight magnesium blocks

Longtail Applications of magnesium slabs in aerospace machining magnesium slabs safely

2 Content Focus

Highlight industryspecific applications and advantages

Include practical tips on handling and machining

3 Structure

Use sections like What Are Magnesium Slabs Benefits of Magnesium in Industrial Use and Safety Tips for Handling Magnesium Slabs

4 Visuals

Add images of magnesium slabs machining processes and enduse applications

Would you like help with an indepth article product descriptions or other tailored content

Zinc Dust

Focus on a mix of highvolume and longtail keywords to drive targeted traffic Examples include

Primary Keywords Zinc dust zinc dust applications zinc dust suppliers

Longtail Keywords How to use zinc dust in coatings benefits of zinc dust in galvanizing zinc dust for corrosion protection

Related Keywords Zincrich primers metal protection with zinc zinc dust safety

X

|

|

“हम केवल बल्क ऑर्डर मात्रा में काम कर रहे हैं”

बस अपना संपर्क विवरण सबमिट करें और हम जल्द ही संपर्क में रहेंगे।

Back to top